Vacuum Forming

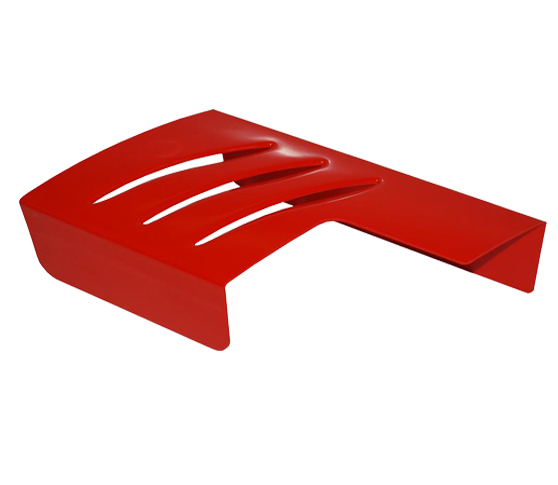

The Plastic Works Ltd have been experts in vacuum formingPlastic Vacuum Forming and all of it’s various methods for a decade. We are able to manufacture vacuum formings in any extruded plastic up to 10mm thick, in any colour, up to 2450mm x 1120mm x 600mm in depth.

The advantage of plastic vacuum forming is its flexibility, as are cost effectiveness and speed of production. Prototypes can be produced quickly and accurately to prove parts before full production tooling is required. Tooling costs are also substantially less expensive in comparison to most other plastic process manufacturing, namely injection moulding, especially on large parts or short production runs.

Vacuum forming offers several processing advantages overvacuum forming derbyshire other forming processes. Unlike other thermoplastic forming processes, where powder or granulate are the starting point, vacuum forming uses extruded plastic sheet.

- Date

- May 18, 2017

The Plastic Works Ltd have been experts in vacuum formingPlastic Vacuum Forming and all of it’s various methods for a decade. We are able to manufacture […]